Latest Collision Repair Technologies at Blalock Auto Center

Introduction to Cutting-Edge Collision Repair Technologies

In the ever-evolving world of automotive repair, Blalock Auto Center is at the forefront of adopting the latest collision repair technologies. These advancements not only ensure that vehicles are restored to their pre-accident condition but also enhance efficiency and precision in repair processes. Let's explore some of the groundbreaking technologies that are revolutionizing collision repair at Blalock Auto Center.

3D Scanning and Damage Assessment

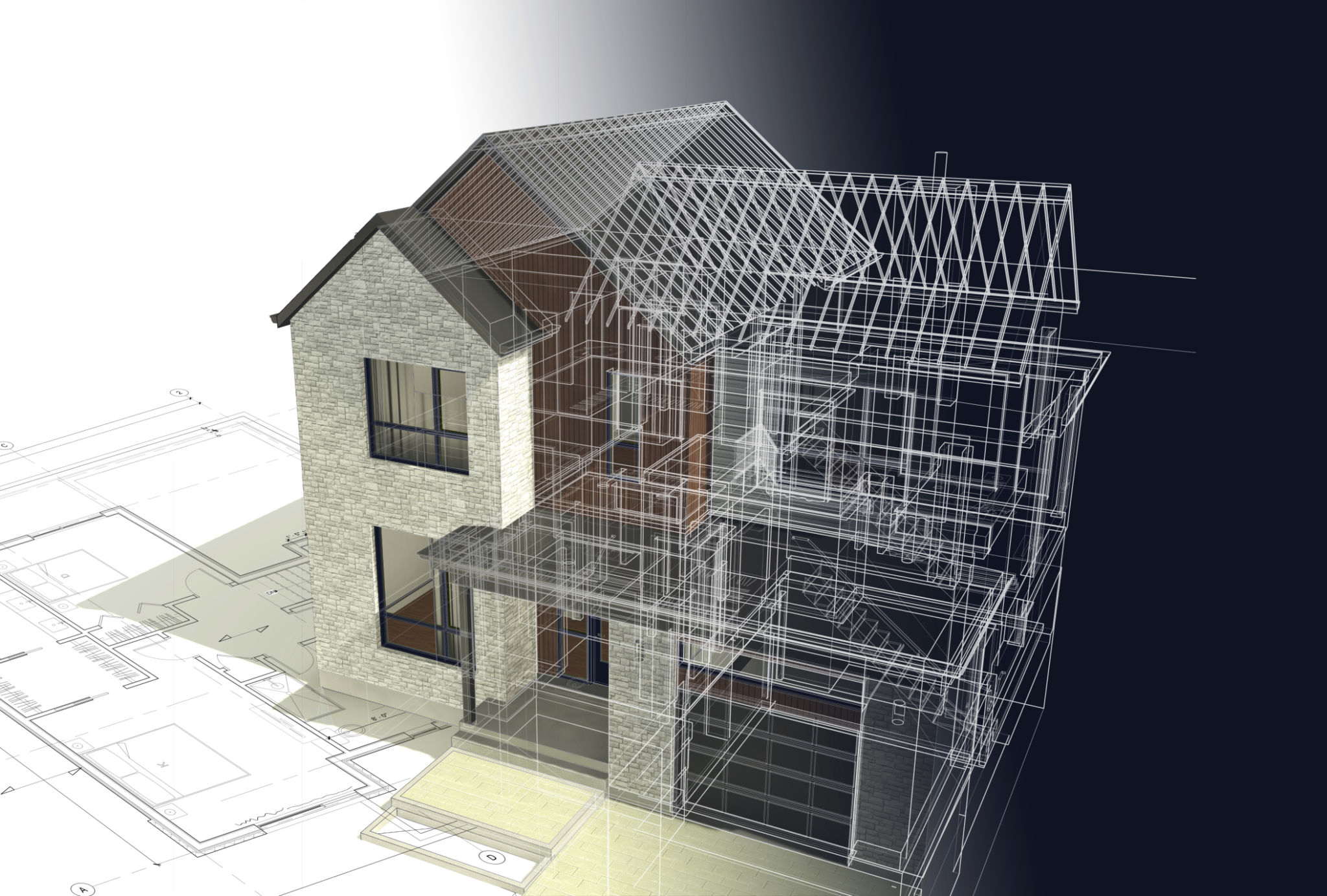

One of the most significant innovations in collision repair is the use of 3D scanning technology. At Blalock Auto Center, this advanced tool enables technicians to create accurate digital models of damaged vehicles. By capturing detailed images from various angles, 3D scanners help in identifying even the most subtle deformations.

This technology not only improves accuracy but also speeds up the damage assessment process. Instead of relying solely on visual inspections, technicians can now have a comprehensive view of the vehicle's condition, ensuring no issue goes unnoticed.

Computer-Aided Design (CAD) for Repair Planning

The integration of Computer-Aided Design (CAD) systems in repair planning has been a game-changer for Blalock Auto Center. CAD software allows technicians to devise precise repair plans by simulating various repair scenarios. This technology aids in determining the most effective techniques and materials needed for restoring a vehicle.

By using CAD, Blalock Auto Center can ensure that repairs are not only efficient but also maintain the structural integrity and safety of the vehicle. This meticulous planning process minimizes errors and reduces repair times significantly.

Laser Frame Alignment Systems

A critical aspect of collision repair is ensuring that a vehicle's frame is perfectly aligned. Blalock Auto Center employs laser frame alignment systems to achieve unparalleled precision in this regard. Unlike traditional alignment methods, laser systems provide real-time measurements and adjustments, ensuring that every millimeter is accounted for.

This technology guarantees that vehicles are returned to their original specifications, which is crucial for maintaining safety and performance. By using laser frame alignment, Blalock Auto Center enhances customer satisfaction by delivering impeccable results.

Robotic Welding and Paint Systems

Automation plays a crucial role in modern collision repair, and Blalock Auto Center has embraced robotic welding and paint systems. These robots deliver consistent and high-quality results by precisely following programmed instructions. Robotic welding ensures strong and reliable welds, essential for vehicle safety.

Additionally, robotic paint systems offer perfect color matching and even application, resulting in flawless finishes. These automated systems not only enhance the quality of repairs but also improve efficiency by reducing manual labor and error rates.

Conclusion: The Future of Collision Repair

The adoption of these latest technologies at Blalock Auto Center underscores their commitment to excellence in collision repair. From 3D scanning and CAD planning to laser alignment and robotic automation, each innovation contributes to superior results and customer satisfaction. As technology continues to advance, Blalock Auto Center remains dedicated to staying ahead of the curve, ensuring that every repaired vehicle meets the highest standards of quality and safety.